A force sensor is a device that measures the amount of force applied to an object. It works by converting mechanical force—such as tension, compression, pressure, or torque—into an electrical signal that can be measured and recorded. These sensors are essential tools in engineering, manufacturing, automation, and testing applications where precise force measurement is critical.

Force sensors are designed to detect changes in force and provide real-time feedback. Whether it’s weighing a package or controlling the grip strength of a robotic arm, force sensors help ensure accuracy and consistency in a wide range of processes.

Common Types of Force Sensors

Strain Gauge Sensors

These sensors operate on the principle that the electrical resistance of a wire changes when it is stretched or compressed. When force is applied, the sensor deforms slightly, altering its resistance. This change is measured and converted into a force reading.

Load Cells

Load cells are one of the most widely used force sensors. They often incorporate strain gauges and are specifically designed to measure weight or load. They come in various forms such as beam, compression, and tension types.

Piezoelectric Sensors

These sensors use materials that generate an electrical charge in response to applied mechanical stress. They are highly sensitive and ideal for measuring dynamic and high-frequency force changes.

Capacitive Force Sensors

These sensors detect changes in capacitance between two surfaces as they move closer or farther apart due to applied force. They’re useful for applications requiring high sensitivity and fast response times.

Force-Sensing Resistors (FSRs)

FSRs change their resistance when pressure is applied. They’re simple and cost-effective, often used in applications where precise force measurement isn’t critical, like touch-sensitive devices.

How Do Force Sensors Work?

Force sensors function by converting an input mechanical force into an output signal. Here’s a simplified breakdown of the process:

- Application of Force: When a force is applied to the sensor, it causes a physical change in the sensing element.

- Physical Deformation: Depending on the sensor type, this might mean a change in shape, pressure, or spacing between elements.

- Signal Conversion: This physical change alters electrical properties like resistance, capacitance, or charge.

- Signal Processing: The altered electrical signal is amplified and conditioned.

- Output Generation: The processed signal is converted into a readable output, often shown on a digital display or sent to a control system.

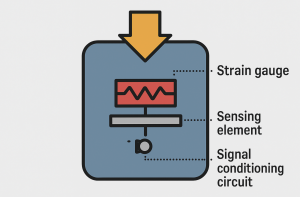

Key Components Inside a Force Sensor

- Sensing Element: The core component that physically reacts to the applied force.

- Signal Conditioning Circuit: Amplifies and filters the raw signal from the sensing element.

- Output Interface: Converts the conditioned signal into a readable format, such as analog voltage, current, or a digital signal.

Some sensors may also include temperature compensation and overload protection features to improve performance and longevity.

Applications of Force Sensors

Force sensors are used in a broad range of applications, including:

- Manufacturing and Automation: Monitoring machine load, controlling robotic arms, and ensuring process consistency.

- Robotics: Enabling responsive touch and pressure-sensitive feedback in robotic systems.

- Medical Devices: Measuring pressure in prosthetics or during surgical procedures.

- Automotive and Aerospace: Testing components under stress and monitoring load during operation.

- Consumer Electronics: Power-sensitive buttons, touchpads, and gaming controllers.

Choosing the Right Force Sensor

Selecting the appropriate force sensor depends on several factors:

- Force Range: Ensure the sensor can handle the expected minimum and maximum forces.

- Accuracy: Choose a sensor with a suitable accuracy for the application.

- Environmental Conditions: Consider temperature, humidity, and exposure to chemicals or vibrations.

- Size and Shape: The sensor must fit within the mechanical design of the system.

- Output Type: Match the sensor’s output with your data acquisition system or controller.

Proper sensor selection helps achieve accurate measurements and extends the device’s lifespan.

Installation and Best Practices

- Correct Mounting: Align the sensor according to the manufacturer’s instructions to avoid misalignment errors.

- Avoid Overload: Do not exceed the sensor’s rated capacity to prevent damage.

- Minimize Noise: Use shielded cables and proper grounding to reduce electrical noise.

- Calibrate Regularly: Periodic calibration ensures consistent and accurate readings.

- Secure Connections: Ensure that electrical connections are tight and protected from environmental conditions.

Maintenance and Lifespan

Force sensors are generally durable but benefit from routine maintenance:

- Visual Inspections: Check for signs of wear, corrosion, or physical damage.

- Calibration: Regularly calibrate the sensor to maintain measurement accuracy.

- Environmental Protection: Use enclosures or protective coatings in harsh environments.

- Avoid Mechanical Shock: Prevent sudden impacts that could damage the sensor.

With proper care, force sensors can maintain performance for years without significant degradation.

Future Trends in Force Sensing

- Miniaturization: Smaller sensors for integration into compact devices and wearables.

- Smart Sensors: Built-in diagnostics and data logging features.

- Wireless Technology: Enabling real-time remote monitoring.

- IoT Integration: Connecting sensors to cloud platforms for advanced analytics.

- Energy Efficiency: Sensors with low power consumption for battery-operated systems.

As technology evolves, force sensors will continue to play a pivotal role in making systems more intelligent, efficient, and responsive. Read more about how to measure movement, torque or force.