In today’s fast-paced world of automation and precision engineering, selecting the right servo motor is crucial. Whether you’re designing a robotic arm, a medical device, or an industrial automation system, the choice of servo motor can significantly impact your project’s success. This guide will walk you through the key considerations when choosing a compact servo motor, ensuring optimal performance and efficiency for your application.

Understanding Compact Servo Motors

Compact servo motors are designed to deliver high performance in a small form factor. They are ideal for applications where space is limited but precision and reliability cannot be compromised. These motors are commonly used in robotics, medical devices, aerospace, and industrial automation.

Key Factors to Consider

1. Size and Form Factor

The primary advantage of compact servo motors is their small size. However, it’s essential to ensure that the motor’s dimensions align with your application’s spatial constraints. Consider the motor’s length, diameter, and mounting options.

2. Torque and Speed Requirements

Determine the torque and speed your application demands. Compact servo motors come in various torque ratings, and selecting one that meets your specific needs is vital. Remember that higher torque often comes at the expense of speed, and vice versa.

3. Voltage and Current Specifications

Ensure that the motor’s voltage and current ratings are compatible with your system’s power supply. Operating a motor outside its specified voltage range can lead to inefficiencies or damage.

4. Feedback Mechanisms

Feedback devices like encoders or resolvers provide information about the motor’s position, speed, and direction. Choose a motor with the appropriate feedback mechanism for your control system to ensure precise motion.

5. Environmental Conditions

Consider the environment in which the motor will operate. Factors like temperature, humidity, and exposure to dust or chemicals can affect motor performance. Select a motor with suitable ingress protection (IP) ratings and materials to withstand these conditions.

Advantages of Customizable Compact Servo Motors

Opting for a customizable compact servo motor offers several benefits:

Tailored Performance: Customize torque, speed, and voltage ratings to match your application’s exact requirements.

Optimized Integration: Design motors that fit seamlessly into your system, reducing the need for additional components or modifications.

Enhanced Reliability: Select materials and designs that withstand specific environmental challenges, ensuring longevity and consistent performance.

HDD Servo: Your Partner in Precision

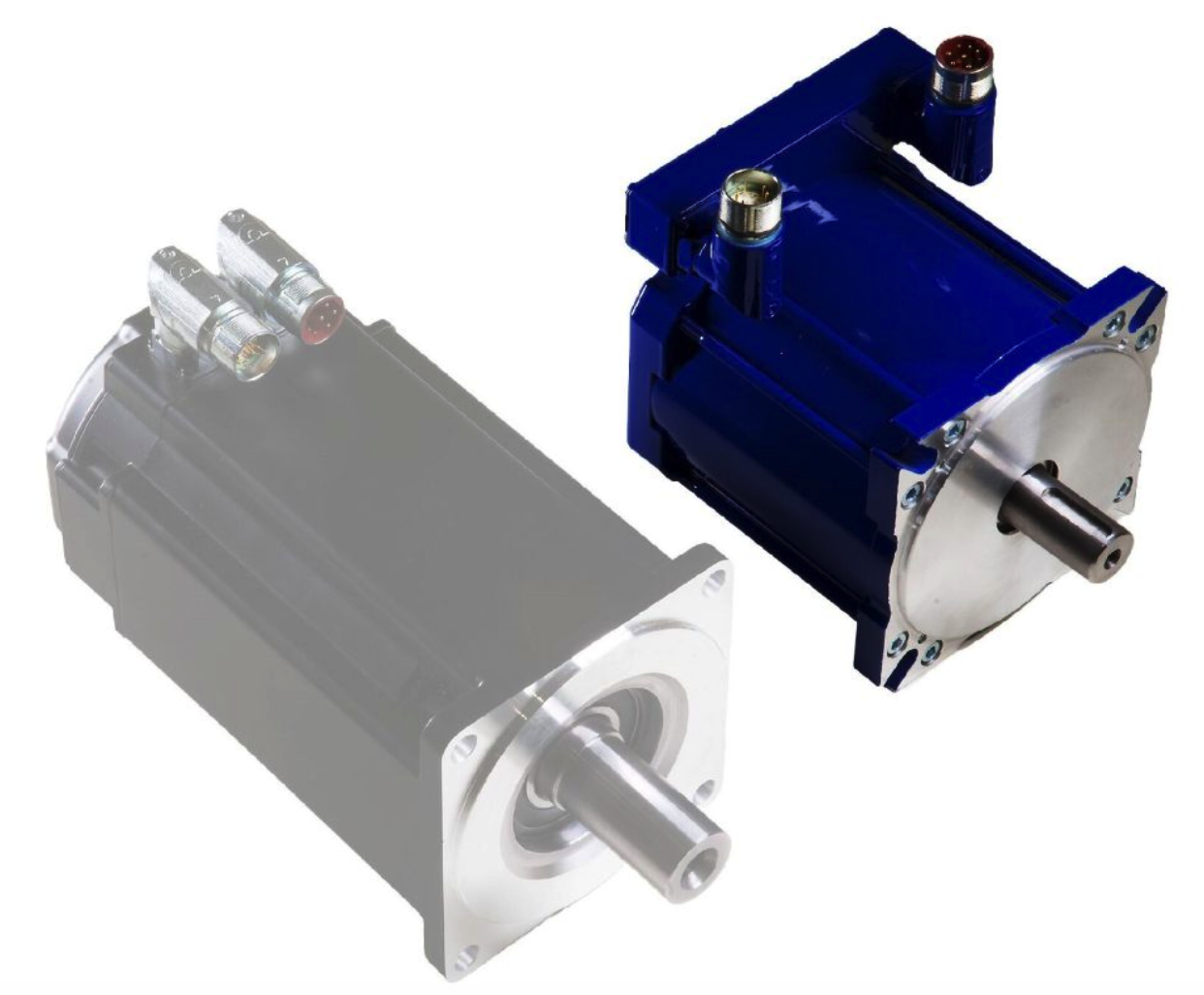

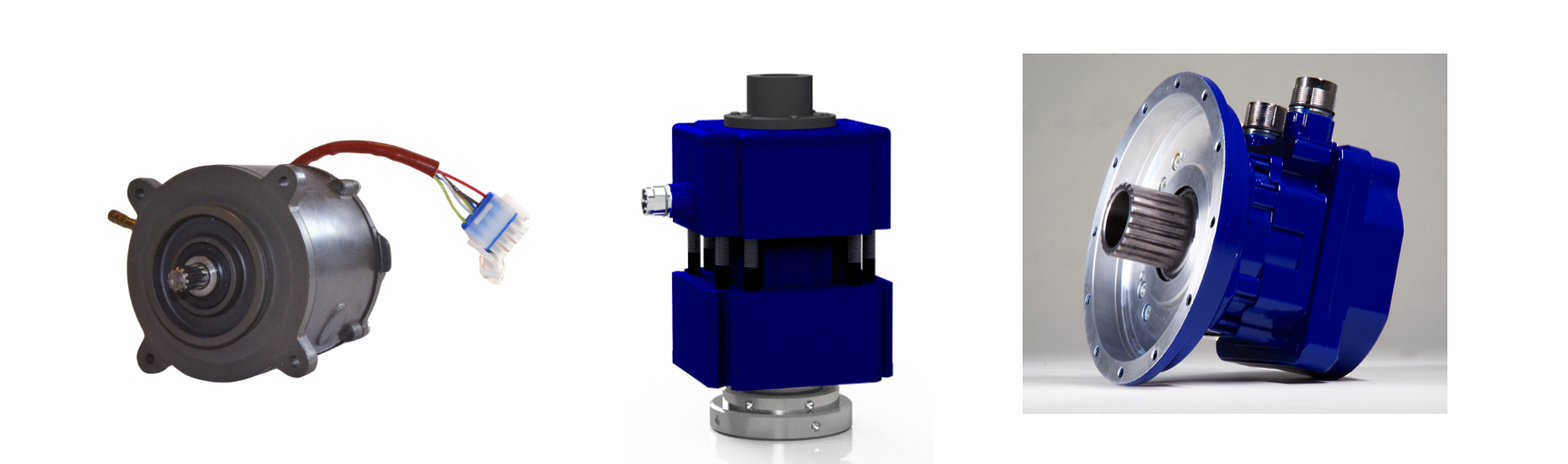

At HDD Servo, we specialize in ultra-compact AC and DC industrial servo motors tailored to your unique needs. Our innovative stator design allows us to offer motors that are up to half the size of our competitors’, without compromising on power or efficiency.

Whether you require solid shaft, hollow shaft, or internal coupling motors, our team is equipped to deliver solutions that fit your application’s demands. We also offer low voltage options and open frame designs for specialized integrations.

Our commitment to customization ensures that you receive a motor that not only fits your spatial constraints but also meets your performance criteria. With a focus on quality and customer satisfaction, HDD Servo is your trusted partner in motion control solutions.

Ready to find the perfect compact servo motor for your application? Reach out to our team at HDD Servo for expert guidance and customized solutions.

Email: info@hddservo.com

Phone: +46 8 86 87 80

Let us help you drive your innovation forward with precision and efficiency.